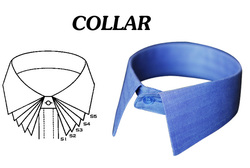

COLLAR

Collar making : - poor interlining fusing such as bubble formed, Resin of interlining not completely fused to fabric and easy caused fabric and interlining separation after garment washed, Over heat to cause yellowish shape.

Collar point should be sharp and without damage. Under fabric extended and exposed outside at edge, plastic stay at collar point position not accurate, Irregular collar top stitch.

Puckering along joining seam of collar fall and collar stand collar fall point Position not accurate at collar stand point and caused collar overlap or too far, Apart after button closed, Poor collar stand point shape, Collar stand point, Fabric extend and exposed outside at edge.

Collar Attaching : - Shoulder and center back botch mark not accurate, Front neckline length two sides uneven length due to shoulder notch mark is incorrect. Back neckline one side shirring due to center back notch mark not at accurate center back position, Collar notch marks not accurately matched with body notch marks position Big problems, collar stand twisted due to notch marks of upper fabric and inside fabric not accurately matched. Lock stitch machine feeding mechanism motion.

Collar point should be sharp and without damage. Under fabric extended and exposed outside at edge, plastic stay at collar point position not accurate, Irregular collar top stitch.

Puckering along joining seam of collar fall and collar stand collar fall point Position not accurate at collar stand point and caused collar overlap or too far, Apart after button closed, Poor collar stand point shape, Collar stand point, Fabric extend and exposed outside at edge.

Collar Attaching : - Shoulder and center back botch mark not accurate, Front neckline length two sides uneven length due to shoulder notch mark is incorrect. Back neckline one side shirring due to center back notch mark not at accurate center back position, Collar notch marks not accurately matched with body notch marks position Big problems, collar stand twisted due to notch marks of upper fabric and inside fabric not accurately matched. Lock stitch machine feeding mechanism motion.

SLEEVE PLACKET AND CUFF

(i) Sleeve placket Sleeve placket not accurate fuse in 14 cm length poor placket triangle top shape placket not properly laid after sewing, puckering placket, Uneven placket width.

(ii) Sleeve pleat and seaming pleat position not accurate, pleat folding not correct, pleat folding size not correct,seaming allowance not accurate, Any one of the above defect will caused the sleeve hole width not match to cuff length, it will form puckering or fabric stretching during cuff attaching sewing.

(iii) Sleeve cuff making : - A void interlining fusing problem same as collar, Not completely fusing, Over heating to cause

Yellowish shape. Not using correct fusible interlining to cause fall fusing test and yellowish shade. poor cuff shape particular at round corner position. Under fabric extended and exposed outside at edge. Cuff length not correct. Uneven cuff width.

(iv) sleeve cuff attaching : - Puckering cuff attaching, Fabric stretched , Twisted cuff, Irregular top stitch, Back stitch less then less then 4 stitch to caused insecurity back stitch, Round top stitch not up the near point of horizontal double stitch line. Side seam not all folding backward or in variety direction folding.

(ii) Sleeve pleat and seaming pleat position not accurate, pleat folding not correct, pleat folding size not correct,seaming allowance not accurate, Any one of the above defect will caused the sleeve hole width not match to cuff length, it will form puckering or fabric stretching during cuff attaching sewing.

(iii) Sleeve cuff making : - A void interlining fusing problem same as collar, Not completely fusing, Over heating to cause

Yellowish shape. Not using correct fusible interlining to cause fall fusing test and yellowish shade. poor cuff shape particular at round corner position. Under fabric extended and exposed outside at edge. Cuff length not correct. Uneven cuff width.

(iv) sleeve cuff attaching : - Puckering cuff attaching, Fabric stretched , Twisted cuff, Irregular top stitch, Back stitch less then less then 4 stitch to caused insecurity back stitch, Round top stitch not up the near point of horizontal double stitch line. Side seam not all folding backward or in variety direction folding.

SEWING OPERATION DEFECTIVE CHECKING POINTS

(a) pocket making and attaching:-

(i) Poor pocket shape due to poor pocket pressing.

(ii) Poor pocket shape due to poor sewing operation

(iii) Slanted pocket position.

(iv) Not accurate pocket position from center front and high shoulder point.

(v) Puckering under side fabric due to feeding mechanism movement of the sewing machine

(vi) Irregular top stitch sewing.

(vii) Pocket mouth easy to be broken.

(viii) Pocket position drill hole marks were not completely covered by pocket ( If use drill hole making position)

(i) Poor pocket shape due to poor pocket pressing.

(ii) Poor pocket shape due to poor sewing operation

(iii) Slanted pocket position.

(iv) Not accurate pocket position from center front and high shoulder point.

(v) Puckering under side fabric due to feeding mechanism movement of the sewing machine

(vi) Irregular top stitch sewing.

(vii) Pocket mouth easy to be broken.

(viii) Pocket position drill hole marks were not completely covered by pocket ( If use drill hole making position)

FRONT PLACKET

(i) Poor interlining attached sewing in which to cause very Crease or bubble. Uneven placket width, Interlining position not at edge of placket.

(ii) Puckering placket Upper and lower placket not in same length. Should make in same length next start operation shape of center from after button closed due to cut hem at center front in horizontal straight line But after hemming sewing, it will caused center front of hem in v shape. So, center front should be a little bit longer, then it will cause center front straight after hemming sewing finished.

(ii) Puckering placket Upper and lower placket not in same length. Should make in same length next start operation shape of center from after button closed due to cut hem at center front in horizontal straight line But after hemming sewing, it will caused center front of hem in v shape. So, center front should be a little bit longer, then it will cause center front straight after hemming sewing finished.